With a little over a year until the launch of the ambitious Surface Water Ocean Topography (SWOT) mission, the Satellite Altimetry Calibration and Validation sub-Facility reached a major milestone in its preparations.

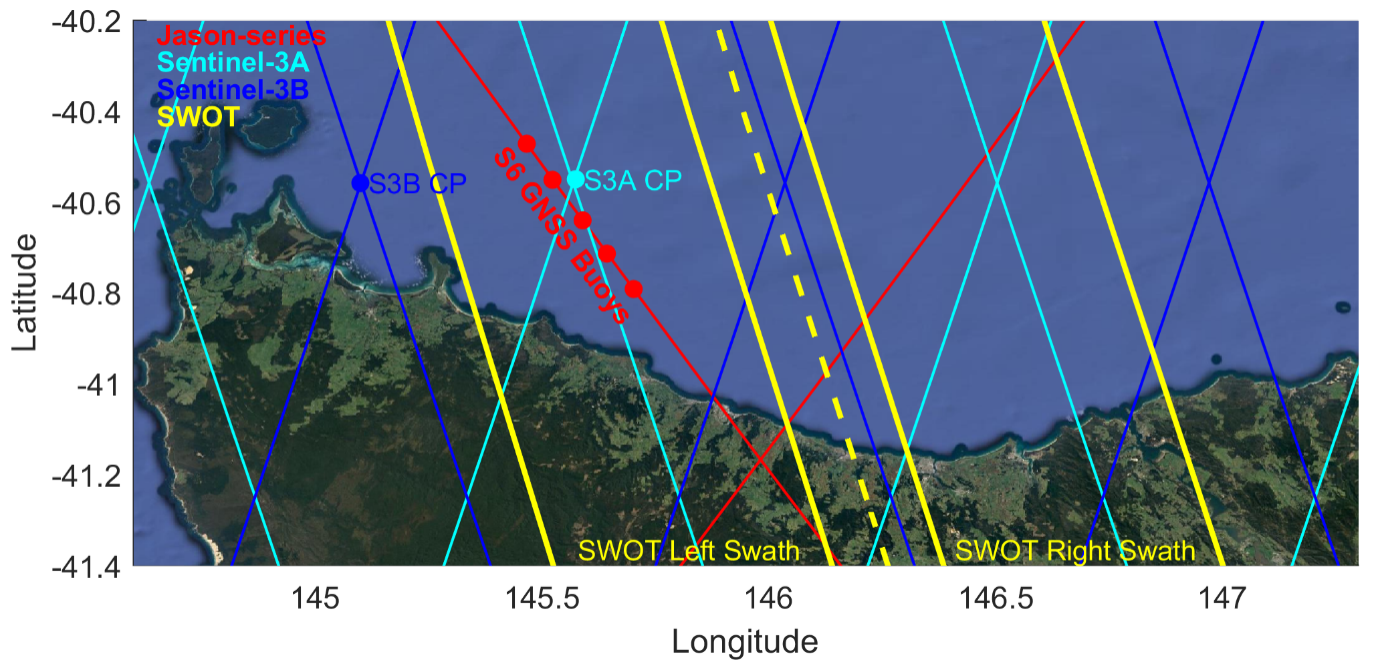

Six new surface buoys designed to precisely observe sea surface height (SSH) have completed their first deployment in Bass Strait over a suite of sub-surface moorings – the buoys were deployed along the ground track of the Jason-series sea-level reference missions. This first trial deployment will contribute to the validation of high-resolution data from the current reference mission known as Sentinel-6 / Michael Freilich which launched in November 2020.

The buoys are designed to fill a technology gap in allowing sustained, high-rate and high-precision observations of SSH along the ground track of existing altimeter missions, and across the broad swath of SWOT observations following its launch.

To complement the surface observations, the IMOS sub-Facility has developed and deployed new moored current, wave, pressure inverted echo sounder instrumentation (CWPIES) which are deployed at specific comparison points under the surface buoys. Together, the sub-Facility can then derive an accurate in-situ picture of SSH variability along track which provides an important contribution to the global validation effort of sea level derived from satellite altimetry. The most recent deployment of three CWPIES instruments were successfully retrieved in October 2021.

Central to the surface buoys are geodetic grade Global Navigation Satellite Systems (GNSS) receivers, coupled with high-rate inertial sensors to observe platform orientation. We’ve worked closely with Xeos Technologies (Canada) to customise our GNSS receivers for the unique challenges of this application. Each buoy is equipped with solar charging and provides remote status of health information as well as Iridium-based location updates, all of which is vital to supporting future extended deployments.

The fabrication of these new surface buoys has involved a collaborative effort between IMOS staff and various local Tasmanian businesses. Particular thanks go to the University of Tasmania Engineering team, Scielex, Mitchell Plastic Welding, Xanderware and Saunders & Ward for their support.